Print large industrial parts. Ultra fast

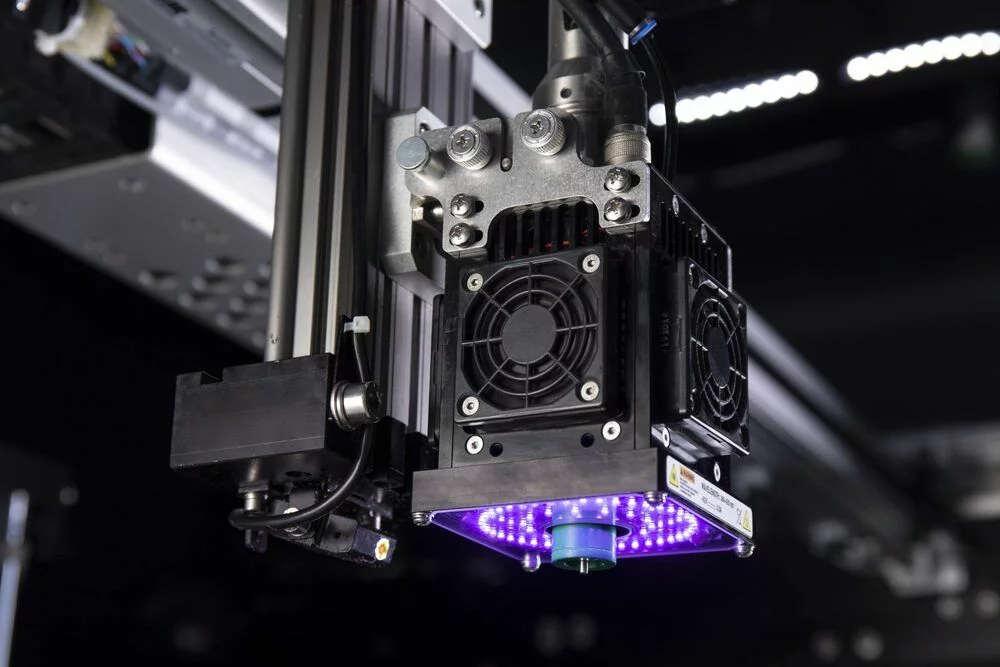

Massivit’s widely-used GDP technology, installed across 40 countries, leverages instantly-curing photo polymer materials that cure on-the-fly. Print large, complex components at 30 times the speed of other technologies. Create durable, lightweight composite parts with minimal waste. Produce industrial FRP train parts or elegant, composite marine components.

Advanced features for workflow efficiency

The Massivit 5000’s Dual Material Mechanism allows you to simultaneously print with a different material on each print head. Benefit from user-friendly slicing software with automated file preparation. Learn about the system’s specialized print modes.

Ultimate flexibility

Choose from a range of layer thicknesses that cater to both high-definition applications and tight turnovers: 0.5 mm, 0.8 mm, 1 mm, 1.3 mm, 1.5 mm. Benefit from an array of industrial-grade materials designed to meet specific industry needs including flame resistance, impact resistance, and transparency.

“Massivit 3D technology is a game changer – simply because of the speed and size you can print.”

-Jason Rowe, Sales Manager, CNC World