Fast and Cost-Effective Production

of Large Tooling for Composites Manufacturing

The MTB is a large format, digital, hybrid, 3D printing system that shifts the paradigm for additive manufacturing by consolidating two technologies into one, using Massivit 3D’s Cast-In-Motion (CIM) process.

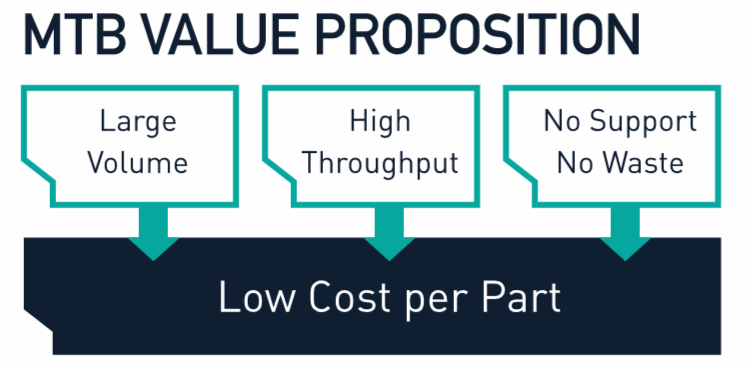

WHY MTB?

Large tools & molds traditionally used for producing fiber-reinforced composite parts are expensive, slow-to-build, wasteful, and require extensive, manual skilled labor. The MTB brings to market enormous time- and cost-saving benefits for the manufacturing of large tooling:

- Shorten production time of molds by 80%

- Save up to 90% of manual labor

- Significantly reduce tool costs

- Simplify production, achieve higher yield

- Simplify supply chain and reduce required stocks

- Reduce waste of expensive materials

How the MTB Solution Works

- The tool pattern is created with a sacrificial, UV-curable gel using Massivit 3D’s patented Gel Dispensing Technology (GDP).

- The desired tool is produced by casting any of a variety of dual-component thermoset engineering materials that closely match the mechanical and thermal process requirements.

- Once the 3D printed tool is immersed in water, the sacrificial pattern material breaks off, leaving the desired mold, ready to use.

TECHNICAL ADVANTAGES

- Design freedom allows mold production of function-oriented, intricate geometries

- Better and faster tool design cycle – including many features – reduces iterations

- Release production equipment increases overall capacity

- CAD part to CAD mold design enables improved accuracy, consistency and higher reliability

- Versatility and multiple casting materials optimize the use of the system

TECHNOLOGY

Massivit 3D’s disruptive, end-to-end tool & mold making solution comprises pioneering hardware, software and chemistry. It facilitates fast, efficient and waste-less manufacturing with unlimited size and volume capabilities. Massivit 3D’s technology is protected by a wide intellectual property portfolio containing 57 active patent assets.

Contact Us

Fill out the form to find out more about significant time and cost-saving benefits for production available with the Massivit 3D Tool Builder.

MASSIVIT 3D

Massivit 3D Printing Technologies Ltd. (www.massivit3D.com) is a pioneer of large format 3D printing solutions comprising 3D printing systems, software, consumables, customer support, and professional services. Leveraging its proprietary Gel Dispensing Printing (GDP) technology, the company’s solutions enable the swift production of large format parts.

Massivit 3D’s initial portfolio of solutions were launched commercially in 2016. Founded in 2013 by a team of recognized industry experts, Massivit 3D is headquartered in Lod, Israel, and provides its worldwide community with end-to-end services supported through an extensive dealer network.