UAVs – an “Exponential Technology”

Drones and robots are being utilized for all manner of traditionally manpower-based tasks in agriculture, horticulture, delivery, surveillance, mapping, monitoring, logistics, inspection, maintenance, and of course, filming.

But what’s interesting is the concept of this “exponential technology” – as Forbes coins it – due to the fact that drone innovation is based on multiple underlying technologies, each of which is, in its own right, advancing at an accelerated rate:

- geo-positioning systems

- propulsion technologies

- sensors

- flight control software

- battery technologies

In 2023, the drone and UAV market was valued at USD 29.6 Billion and is projected to grow to USD 66 billion by 2030 (according to Market Research Future).

Why Composite Materials?

Lighter, Stiffer, Faster.. By nature, drones must fulfill particular criteria related to aerodynamics, speed, and weight. Due to their dependency on batteries, drone covers must be as lightweight as possible (to conserve battery power) – hence the reliance on composite materials. In addition, drones can be fragile and vulnerable, so the use of stiff and tough materials like carbon provide protection and durability, allowing them to last longer.

A Bit About Drone Types

So, what are the different types of drones and which categories are used for each industry and application?

Autonomous Drones

Autonomous drones are UAVs equipped with sensors and software to operate independently. They perform tasks like aerial surveying, mapping, monitoring, and inspection, following predefined routes and collecting data with high precision and efficiency.

Semi-Autonomous Drones

Semi-autonomous drones require human input but can perform tasks independently. They are used for photography, videography, and recreational flying, as well as in situations requiring human oversight, like search and rescue missions or security surveillance.

Remote-Operated Drones

Remote-operated drones, or manual UAVs, are controlled by human operators via remote control or ground station, requiring continuous input for navigation and task execution. They are versatile tools used in industries like aerial photography, filming, agriculture, and emergency response, offering real-time control and maneuverability for tasks requiring precision.

Tooling and Composite Manufacturing for Drones & UAVs. What are the Bottlenecks?

Due to the surge in demand for unmanned aerial vehicles, there is an inherent growing demand for faster tooling methods. UAVs are now required to be produced on a relatively tight turnaround, but without compromising on quality. Traditional and current drone production workflows are largely reliant on machining aluminum blocks for molds. This is extremely time-consuming and dependent on efficient supply chains. It also generates enormous material waste.

Newly available tooling methods, available with industrial 3D printing, allow service providers and manufacturing OEMs to expedite the design phase and manufacturing of custom UAVs. This enables the production of molds within just a few days instead of months – simplifying the workflow, cutting costs, and avoiding material waste.

How Additive Manufacturing Comes into the Picture

One digital technology that is driving production efficiencies for drones is Cast In Motion. Cast In Motion is designed to overcome known bottlenecks in mold production for composites manufacturing. It was developed to replace existing tooling methods that are slow, expensive, wasteful, and require extensive manual skilled labor. This automated system shortens mold production time by up to 80% and is the basis for Massivit’s 10000 additive manufacturing series.

With automation at the heart of this innovation, Cast In Motion technology enables the digital production of industrial molds for a range of composite material end products including many types of drones and robots (autonomous, semi-autonomous, remote-operated as well as multi-rotor, single-rotor, and fixed wing).

How Does it Work?

Massivit’s Cast In Motion technology prints an initial sacrificial shell in any required geometry based on a CAD file or 3D scan, and then casts an epoxy casting material into that shell as it builds. The encapsulated mold is then placed in an oven to enhance its mechanical properties. It is immersed in a bath of plain water allowing the wash away shell to crumble away, leaving the near-to-shape mold. The mold can be milled or sanded if needed and used for hand layup with carbon fiber or vacuum bagging at minimum pressure.

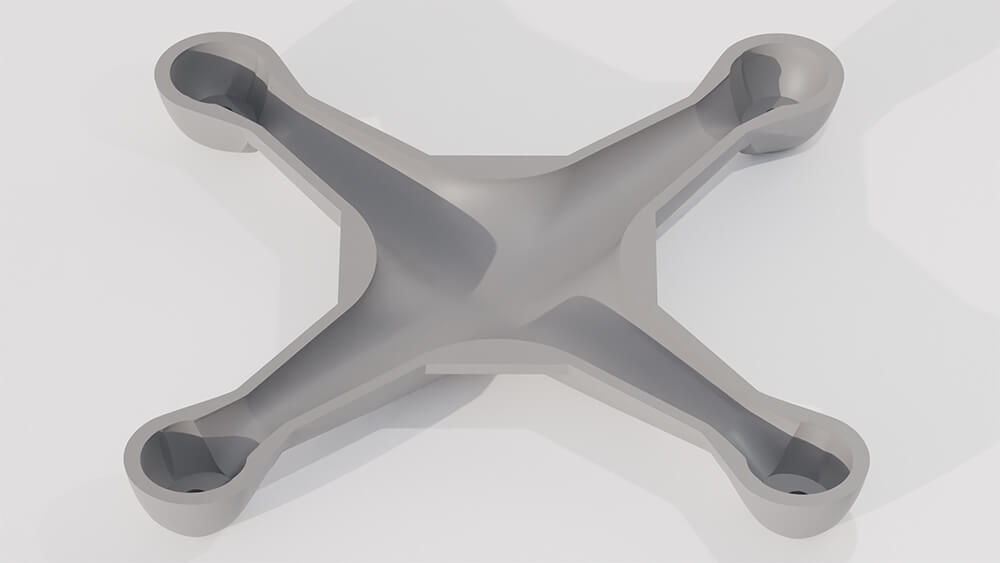

The 3D printed mold pictured above has been designed and 3D-printed for the top cover of a multi-rotor, autonomous drone (quadcopter) used to transport packages including medical supplies and food. It is an epoxy-based mold that has been directly printed on a Massivit 10000-G additive manufacturing system in just 15.5 hours, without the need for a master tool.

Massivit’s industrial 3D printing technologies are an exceptionally good match for producing custom-designed exteriors and tooling for drone production. Based on high-speed direct printing and casting innovation, these large-scale 3D printers enable large composite components to be rapidly produced in any geometry according to a CAD design file or 3D scan of an existing model. It even enables flanges to be printed as part of the mold.

Casting Materials for Drone Molds

Massivit’s unique casting material, CIM 500, enables high-speed tooling as well as excellent mechanical properties: high HDT and a low CTE. It provides the only isotropic 3D printed mold on the market.

What About Rapid Prototyping for Drones?

In terms of design and development, rapid prototyping for drones and UAVs can be produced and iterated with ease on a Massivit 10000-G to optimize essential factors such as lift, thrust, aerodynamics, and non-visibility. Additive manufacturing can significantly speed up product development and cut production costs. In addition, parts that are 3D printed on a Massivit system can be produced hollow, allowing for a low weight and relatively low density.

“Exponential” Technology Demands New Processes

Manufacturing methods have been somewhat stuck in the past. Combining the latest innovative propulsion technologies with advanced geo-positioning systems is inspiring. Overall production workflows must be rethought to match the need for lean production of new technologies in the digital age. Additive manufacturing offers an excellent basis for automating production processes and propelling high-speed creation of drones, UAVs and robots.