Defining Your Objectives: What Sets the Course for Success?

Before delving into the technical intricacies, it’s imperative to define your objectives. What do you intend to 3D print? Whether it’s crafting intricate prototypes for automotive design, bringing costumes, props, one-of-a-kind design prototypes in the film industry, or producing large components for rolling stock and trams, understanding your specific needs forms the foundation of choosing the right industrial 3D printer. Consider the applications and parts you plan to produce and evaluate your available turnover time. In alignment with your intended applications and production goals, it’s essential to explore the printing speed capability, the printer size, its complexity, the types of materials available, and the build volume of a given 3D printer.

While 3D printers were originally used for design and development (or “rapid prototyping”), the advancements in 3D technologies now enable industrial tooling as well as direct printing of production parts.

Build Volume: Balancing Size and Efficiency

In the realm of industrial 3D printers, the build volume of a 3D printer is a paramount consideration. How big is “big” and what proportion of your output requires a larger print volume? In addition, it is crucial to also take into account the printing speed for workflow efficiencies. Conduct research about Large Format Additive Manufacturing (LFAM) systems to understand how the latest technologies align with your specific business requirements.

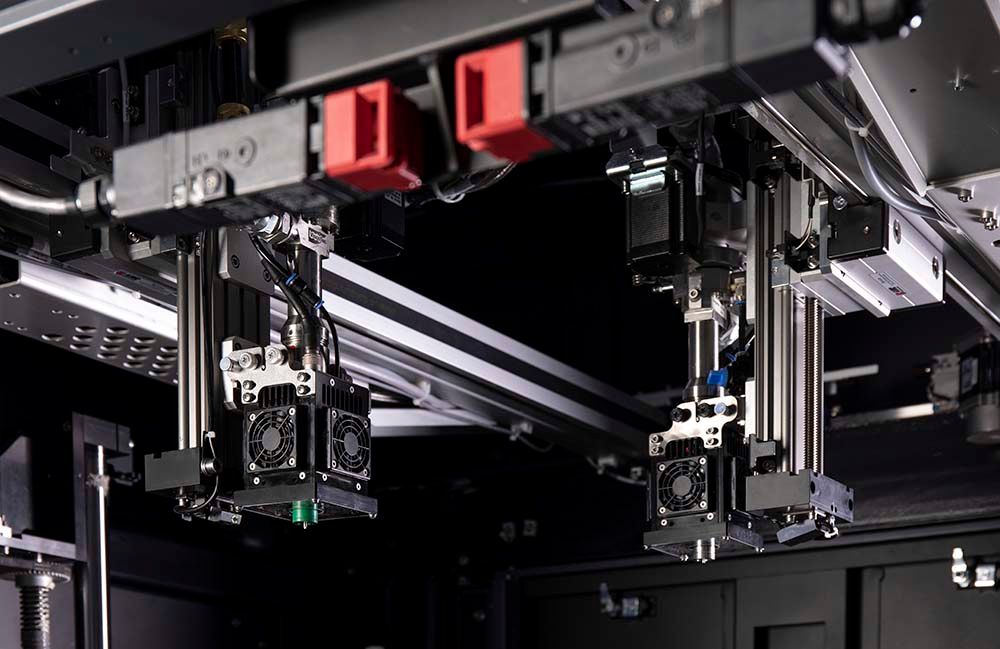

Dual Print Head: Elevating Workflow Efficiency

A dual print head can be a game-changer for workflow efficiency. The ability to simultaneously print two independent components in essence provides the throughput of two printers in one. Moreover, some large-scale printers allow for two different printing materials to be used in parallel, offering manufacturers and fabricators the ability to work on multiple projects at once. Consider this feature, especially if your applications demand diverse materials that benefit from simultaneous printing. This type of flexibility and speed can provide high value on a business level.

Printing Infill Support: Streamlining the Production Journey

Examine how the 3D printer handles support structures, as it directly impacts not only printing time and post-processing efforts, but also your impact on the environment. Obviously, larger parts generally require significantly more printing material for support structures and infill – much of which is not used for the final end part. Look into which technologies allow for printing of hollow parts as this can markedly cut down on your material waste. Massivit’s large-format 3D printers eliminate the need for extensive infill due to their unique gel-based printing materials that have a high viscosity, allowing parts to cure ‘on-the-fly’. This reduces overall printing time but also minimizes material waste, contributing to a more sustainable and cost-effective process.

Range of Materials: Tailoring to Unique Applications

Before diving into the vast material options, create a clear list of applications you intend to print to understand compatibility with your needs. Whether they be production parts, molds, or mockups, the printing materials need to align with your production needs in terms of mechanical properties, turnover requirements, and conditions such as withstanding elevated temperatures, transportation and sea requirements, or flame retardancy. Try to think beyond the final component as LFAM systems can equally serve your needs for custom jigs, fixtures, and prototypes within your workflow. Technical Data Sheets (TDS) are your essential reference when it comes to assessing print materials. Do you need tight tolerances? A specific Heat Deflection Temperature (HDT)? A hydrophobic material for harsh weather conditions? Transparency for an electronics housing?

Printing or Casting Materials?

If part of your output involves tooling or molding applications, consider specific mechanical properties such as CTE (Coefficient of Thermal Expansion) and HDT. Large-scale industrial 3D printers are evolving to respond to age-old market challenges including isotropy. Until recently, additive technologies were not capable of directly printing isotropic parts and molds (due to the inherent ‘layering’ process associated with this technology. New advancements in direct casting now allow molders to digitally cast parts that were previously deemed “unprintable”. This is achieved by directly casting an isotropic mold into a 3D-printed sacrificial shell, thereby overcoming the layering limitation. This is a game changer in terms of replacing existing anisotropic tooling with isotropic molds that expand evenly across all axes in elevated temperatures.

Onboard Camera: Real-Time Monitoring for Unattended Printing

An onboard camera provides the convenience of real-time monitoring, allowing you to keep a watchful eye on your print progress remotely. This feature enables unattended printing, enhancing operational efficiency and reducing the need for constant manual oversight.

Smart Cleaning System: Ensuring Hassle-Free Operation

A smart cleaning system, coupled with computer vision monitoring software, ensures smooth and uninterrupted printing. This automatic feature minimizes the reliance on operators for intervention, contributing to a hassle-free and consistent printing process.

A versatile complement to your toolbox

For many manufacturers and businesses, 3D printers aren’t about replacing existing technologies, but rather expanding their capabilities. They operate independently alongside CNC machines, manual processes, and other tools, offering a powerful solution for specific tasks and applications. Combining additive manufacturing into the production process will allow companies to cut costs, increase efficiency, and improve the end product.

Conclusion

The process of selecting the optimal industrial 3D printer necessitates a thorough examination of your business applications, workflow needs, required materials, and turnover expectations. Key factors such as size, dual print heads, support structures, material compatibility, and sustainability demand careful consideration. By collating these technical and strategic considerations, you can adeptly navigate the landscape of industrial 3D printers, ultimately choosing a printer that harmonizes with your business vision and objectives.

Opting for a cutting-edge printer can serve not only to meet your immediate technical requirements but it can also significantly impact your brand, communicating a commitment to innovation that often goes hand-in-hand with more eco-friendly technologies as well as more advanced capabilities in production speed.