The advent of 3D printing ushered in a new era of possibilities in the evolving realm of manufacturing. When exploring industrial 3D printers and their potential to impact your business, the excitement is tangible. However, amid this excitement, navigating the intricate landscape of technical specifications becomes crucial. This guide aims to empower you, guiding you the choices and assisting you in selecting the right industrial large format 3D printer for your business needs.

Duty-Free attracts crowds at Sydney Airport with gorgeous dragon 3D printed for the Chinese New Year! Extraordinary activation, measuring 4m x 1.5m, was printed by Australia’s Art & Soul Creations on a Massivit 5000

In the world of recreational vehicles (RVs), customization is key. Whether catering to luxury travelers, digital nomads, or adventurous souls, RV manufacturers are constantly seeking innovative ways to meet the diverse needs of their customers. Enter 3D printing, a revolutionary technology that is reshaping the way RVs are designed, produced, and enjoyed across all segments of the market.

First two Materials to be Launched at JEC World Tradeshow, March 5th-7th

There is a remarkable increase in the prevalence of drones (according to Gartner) and they’re not just employed for military purposes.

As yacht designs advance to incorporate stunning, intricate geometries, traditional boatbuilding methods present significant challenges. Read this case study to discover how industrial 3D printers can provide custom manufacturing for super yachts at extraordinarily high speeds.

The marine industry is poised for significant growth, particularly in ship and boat building and repairing, reaching $284.22 billion in 2023. Projections indicate a further increase to $303.65 billion in 2024, reflecting a compound annual growth rate (CAGR) of 6.8 percent.

The pursuit of more advanced vessels has driven innovation in boat building, leading to the development of a range of new manufacturing techniques, alternative construction methods, and materials. These groundbreaking advancements are shaping the future of the industry, paving the way for the efficient creation of elegant yachts, ships, catamarans, and vessels that navigate the world’s oceans.

At the forefront of boatbuilding innovation are advanced materials that push the boundaries of performance and design. Following our first blog exploring commonly used boatbuilding materials, we delve into more advanced materials, their unique properties and their transformative impact on boat construction.

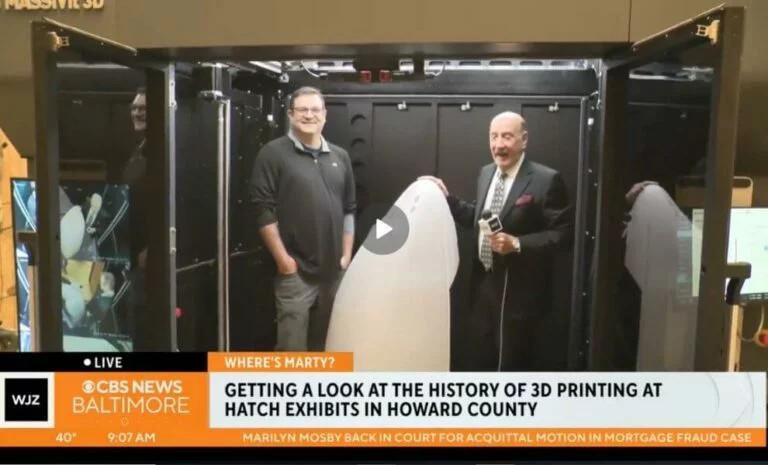

LOD, Israel, January 2nd, 2024 — Massivit 3D Printing Technologies (TASE: MSVT), a leading provider of industrial 3D printing systems, has received an order from Walt Disney Imagineering for the purchase of a Massivit 10000-G, the most advanced of Massivit’s 3D printers.

How National Geographic Museum employs large-scale 3D printing to transport its visitors back into Tutankhamun’s time. This extraordinary experiential exhibit is touring cities across Mexico and the USA

The evolution of boat-building techniques is a testament to human ingenuity and the relentless pursuit of better ways to navigate the world’s oceans. From the humble dugout canoe to the sleek carbon fiber racing yacht, each advancement has pushed the boundaries of what is possible. Over centuries, boat construction has undergone a remarkable transformation, evolving from rudimentary crafts made from natural materials to sophisticated vessels incorporating the latest technological advancements. This 3-part boatbuilding blog delves into the latest techniques and materials boat builders use for contemporary boat manufacturing.

At IAAPA – the largest trade show for the attractions industry – Massivit will demonstrate its CIM 84 material that provides high-speed printing for themed experiences, now with ASTM E84 Fire and Safety Regulations compliance.

ACE award granted at CAMX 2023 tradeshow marks the third award acknowledging Massivit’s disruptive Cast In Motion additive manufacturing product line.

A wide range of high-speed composites tooling and custom manufacturing applications will be on show for Formnext attendees including industrial, large-scale epoxy molds, master tools, jigs, fixtures, functional prototypes, and composite end parts.

CAMX visitors at the Atlanta, GE show will have the opportunity to see the Massivit 10000-G high-speed additive manufacturing system printing a range of industrial custom molds, end parts, master tools, jigs, fixtures, and prototypes throughout the show.

Massivit to Introduce the Massivit 10000-G Additive Manufacturing System to the Maritime Manufacturing Market at the IBEX 2023 Marine Technology Tradeshow in Tampa, Florida on October 3-5

Massivit to Present the Massivit 5000 Industrial 3D Printer and High-Impact Printing Material at IAAPA Expo Europe in Vienna, Austria

An Exclusive Interview with Avi Cohen

Imagine reducing production timelines, slashing inventory costs, and creating complex components with ease. These are just a few opportunities the aerospace industry can unlock with the power of large-scale 3D printing technology.

The automotive industry has always been at the forefront of material innovation. From the early days of steel and aluminum to today’s modern materials, it’s a sector that never stops evolving.

Quando si pensa al processo di costruzione di un’imbarcazione, una stampante è l’ultimo strumento che viene in mente di utilizzare. Tuttavia, la rapida innovazione della stampa 3D rende sempre più necessario disporre di una stampante 3D per far fronte alla concorrenza, alla domanda e per mantenere costi competitivi.

No more posts to show