LOD, Israel, October 25, 2023 — Massivit 3D Printing Technologies (TASE: MSVT), a leading provider of industrial 3D printing systems, has announced that the company will present its Massivit 10000-G additive manufacturing system at the CAMX 2023 tradeshow on October 30th – November 2nd. Event attendees will discover how composites manufacturing bottlenecks can be overcome by using Massivit’s advanced additive manufacturing technology, already adopted in multiple industries including automotive, marine, and consumer products.

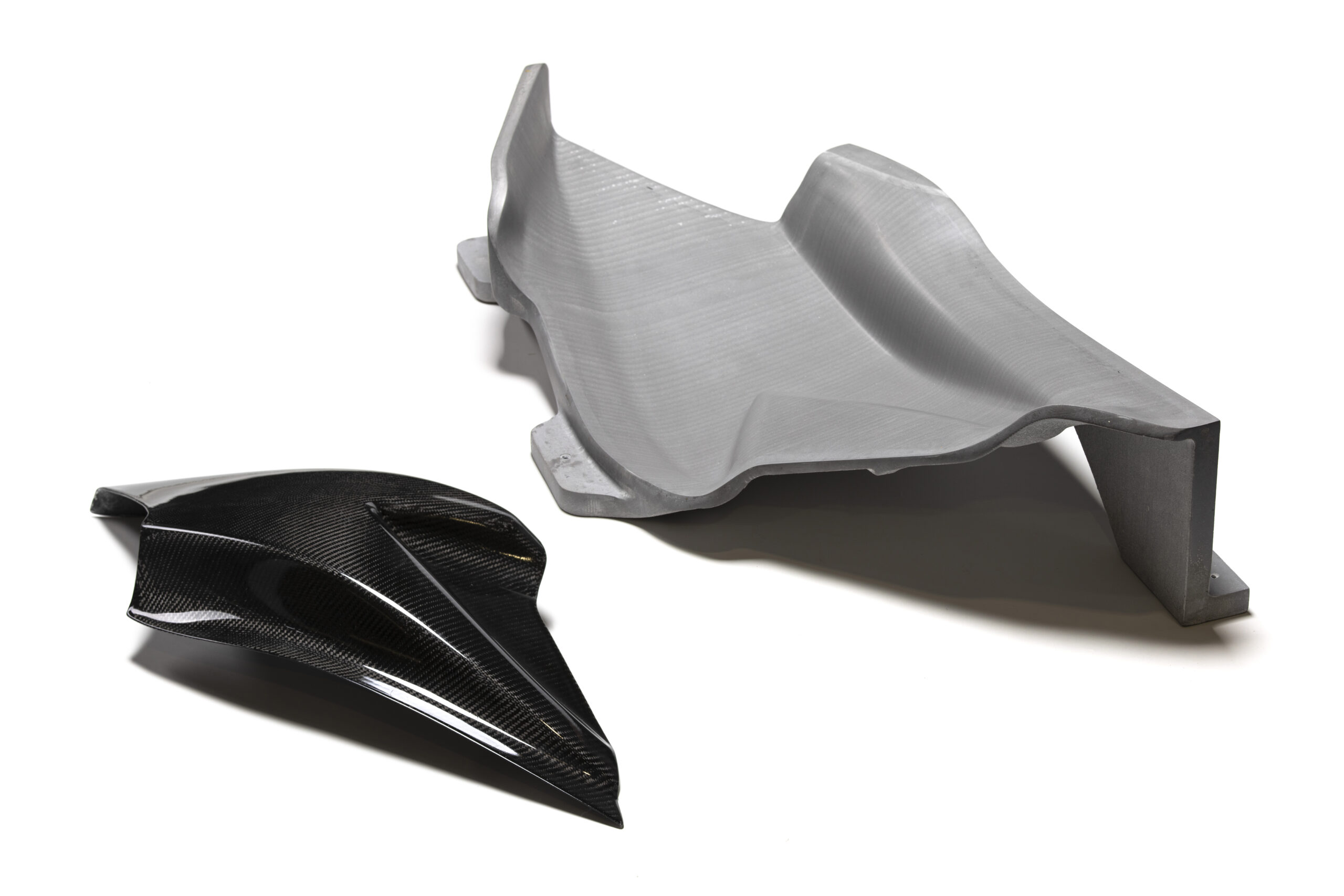

The 10000-G will be showcased via live demonstrations throughout the CAMX show, as well as a range of printed production parts and molds on display.

Visitors to CAMX 2023 can book a personalized demo of the Massivit 10000-G

The Massivit 10000 product line shifts the paradigm for composites manufacturing, enabling high-speed, direct printing and casting of industrial components for a range of composite applications. It allows mold fabricators to reduce their production time by 80% by directly printing an industrial epoxy mold, thereby bypassing the need for a master tool. This additive technology decreases labor-associated costs by up to 90% and significantly reduces material waste associated with current machining methods.

CAMX visitors will learn about a range of available industrial tooling applications including open and closed molds, resin transfer molds (RTM), reaction injection molds (RIM), tooling for thermoforming, and more.

The latest Massivit 10000-G additive system combines these custom tooling benefits with a full range of custom manufacturing applications that were until now available with Massivit’s Gel Dispensing Printing (GDP) product line. GDP supports 8 specialized printing materials offering flame retardancy, high impact resistance, and additional industry requirements. Custom-designed, full-scale railway and marine components can be printed within a matter of hours, saving manufacturers enormous time, costs, and material waste.

Based on the company’s disruptive Cast In Motion technology, the Massivit 10000 product line has accrued a string of industry awards and accolades including the 2021 ACMA ACE Award, the 2022 IBEX Innovation Award for boatbuilding, and selection as a finalist for the upcoming 2023 ACE Award at CAMX 2023.

On October 30th, CAMX will join Massivit in hosting an Industry Tour of the Massivit Americas Experience Center from 8AM-1PM, offering a first-hand exploration of Massivit’s industrial 3D printers, exposure to customer case studies, and an in depth exploration of the key technologies behind the printers. Complimentary transport from the CAMX venue as well as catering is available for this Alpharetta-based event.

Massivit’s CEO, Erez Zimerman, commented “We are honored to have been selected for the second time as a finalist for the upcoming CAMX Awards for Composites Excellence. We previously won this award in 2021. The 10000-G system is taking the manufacturing arena by storm, offering a comprehensive answer to longstanding manufacturing challenges such as manpower shortages and time to market challenges. Our customers across many industries are elated by the possibility to directly produce industrial grade components with high performance materials in a fraction of the time and costs. We are excited to introduce these new possibilities at CAMX.”

Journalists are invited to schedule an interview with Massivit’s CEO, Erez Zimerman via the company’s contacts below.

About Massivit

Massivit 3D Printing Technologies Ltd. (TASE: MSVT) is a leading provider of industrial 3D printing systems for the automotive, marine, railway and additional manufacturing markets. The company’s solutions enable cost-effective production of large, custom parts, molds, and prototypes at unprecedented speed. Massivit’s vision is to transform manufacturing of large parts from traditional processes to ultra-fast, digital fabrication using industrial-grade materials. The company was founded in 2013. Its headquarters are based in Lod, Israel and the company provides its worldwide community with end-to-end services supported through an extensive dealer network.

For additional information, please contact:

Avi Cohen

VP Global Sales & Marketing

Massivit

Email: [email protected]

Yafit Sulimani

Senior Marketing Team Leader

Massivit

Email: [email protected]

For investor relations enquiries, please contact:

Miri Segal Scharia

CEO

MS-IR LLC

Email: [email protected]

+1 917-607-8654