If you produce too few parts, you aren’t able to service customers fast enough. If you produce too many, the cost of keeping stocks of parts that may never be used looms large. So large that oftentimes suppliers will simply discontinue their production.

However, issues such as manufacturing feasibility and storage do not provide the whole story. The full potential of additive manufacturing, also called 3D printing, only becomes apparent when companies consider its effects on the entire supply chain, and ultimately its total cost of ownership (TCO) and the potential benefits of radical changes in product design.

Reducing Inventory with 3D Printing

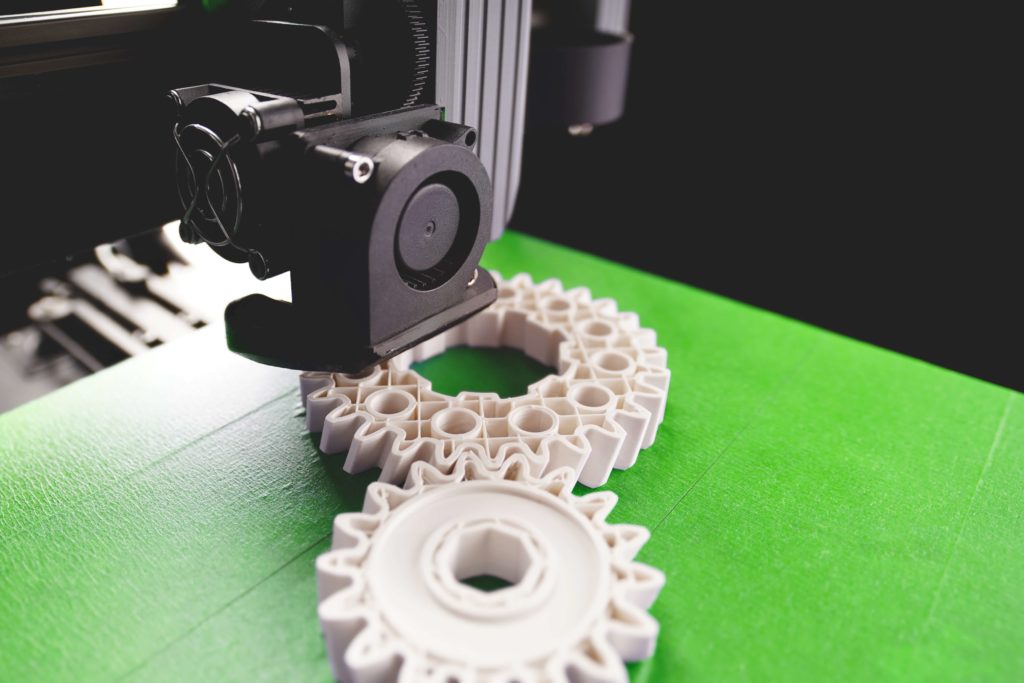

German railroad company Deutsche Bahn (DB) faced the challenge of having to store an ever-increasing amount of spare parts in multiple warehouses for extended periods of time to keep its train fleet (with vehicles older than 40 years) operational.

Given the impact of storage and replacement costs on TCO, the company was determined to reduce the size of its inventories and avoid the risk of unexpected costs (which arise from having to custom-produce replacement parts in small batches). The company researched various technologies and identified 3D printing as the most promising option. It then worked with 3D printing experts to further evaluate the technological and economic feasibility.

The exercise showed that the selected spare parts that met all the railroad’s tests could be successfully printed at a reduced TCO – and that the technology will soon become a very attractive option for extending the life of rolling stock.

As railway operators regularly require spare parts for a broad range of different train and tram models, the build volume of Massivit printers allow railway operators to minimize their inventories of parts such as body panels, and print them in a variety of materials that allow for the properties required for various applications in the rail industry, including resistance to heat, pressure, flame retardancy, and chemicals. Interior parts can also be printed and reinforced with composite materials, enabling the rapid and modular reconfiguration of cabs, passenger cabins, galleys, and more.

3D-Printed Parts on the Rise

A report by consultancy firm PwC shows that both spare parts suppliers and their customers expect the number of 3D-printed parts to increase dramatically; the consulting firm expects that in five years 85 percent of all spare parts suppliers will have integrated 3D printing into their business. There is a strong desire among executives in various industries to integrate 3D printing into their product development and parts operations. However, the impact of the technology will vary significantly depending on the stage in the product lifecycle, where it is used, and the nature of the part being made.

The operational benefits of printing spare parts are clear. Firstly, the number of spare parts that companies need to keep in stock will be significantly reduced, as 3D printing allows companies to move from make-to-stock to make-to-order while maintaining or even improving delivery times. Production interruptions due to tool changes can be reduced to almost zero. And even if additional machining is required, the overall setup time is significantly reduced.

Secondly, parts can be manufactured near where they are needed. As a result, parts are available when customers need them, with shorter lead times and less logistical planning. In these scenarios, no one needs to maintain a stock of spare parts. There is little or no production downtime for changes in machine operation because the manufacturer can provide customers with the specific 3D file for producing the part on demand.

Planning for 3D-Printed Parts

Still, it is unlikely that all replacement parts currently in stock will be replaced by their digital brothers: the obstacles are simply too great. And while people are working hard to address these barriers, there will still be an important role for spare parts warehouses.

In this light, it certainly pays to start researching 3D printing now, so as not to fall behind later. Analyze your parts portfolio: the analysis can cover key performance indicators such as inventory days, minimum order quantity, lead times and total costs. Such analysis allows you to clearly identify where 3D printing will provide the greatest benefit.

For example, extremely old or rarely needed parts are best suited for digitization and possibly 3D printing. This makes sense: newer and frequently needed parts can also be kept in stock for easy access, as there is a constant demand for them; however, parts that are rarely needed should not be kept in physical stock at the expense of the manufacturer. Even for old and rarely used parts, there does remain the challenge of “transforming” parts into 3D printable models, and that often involves some reverse engineering.

Yet, it is clear that 3D-printed parts will be introduced to most production lines at some point. There are already large scale 3D printers which are integral to production in various industries. Leading companies are taking stock, and those ahead of the curve will benefit sooner from the incredible innovation in additive manufacturing.