Print Service Providers (PSPs) share several challenges in common: one of the biggest is the need to deliver projects faster than ever before. While working longer hours could help, many PSPs have discovered that a fast 3D printer is the better answer.

But not just any fast 3D printer. The large format 3D printer that was designed to serve the needs of the visual communications industry.

Fast 3D Printing Helps PSPs Increase Profit Margins

The #1 challenge PSPs face these days is tightening margins due to commoditization and competition. Businesses that want to avoid having to always aim for the lowest bid are finding ways to differentiate their offering, and Massivit is providing the ideal solution.

With Massivit, PSPs add an innovative service to their portfolio, a new technology that offers an ever-expanding list of applications. From a menu of signage options to giant, attention-grabbing retail and exhibition displays and beyond, Massivit cuts the production time down dramatically and puts speed-to-market in the PSPs favor.

The Need For Speed

It is 2019. Everything is expected to be fast. Machines. Communications. And product-to-market delivery time. At an international trade show, PSP owners were asked what their biggest need is:

One of the reasons for this need for speed is customers’ ever-faster production cycle times. Retailers and brands are continually changing their promotions and introducing new consumer products. They need printing support, which is great for your printing business, but the pressure to deliver in time and on time can be intense.

IDC Research Director, Tim Greene, who focuses on the wide format printing industry, confirms:

“PSPs report that one of their biggest challenges is meeting customers’ demands for ever-faster cycle times.” -Tim Greene, IDC Research Director

The Only Super-Fast Large 3D Printer For Visual Communications

Massivit printing solutions were designed to add a dimension to a PSP’s business and enable them to deliver 3D the way it’s demanded — fast. Massivit 3D is faster than any other traditional fabrication method and also every other 3D printer. The unparalleled printing speed is achieved with Gel Dispensing Printing (GDP).

In 2017, all3dp.com spotlighted Massivit 3D’s Gel Dispensing Printing as a new milestone in 3D printing.

There was, and still is, no comparison to GDP for visual communications, entertainment, interior design, and concept prototyping applications that demand fast turnaround. Massivit 3D’s printers are ideal for:

- Print Service Providers, especially those serving brands and advertising agencies

- Sign Makers

- Retail Display Fabricators

- Exhibition and Event Fabricators

- Interior Designers

Once a PSP installs the super fast Massivit 3D printer, the print shop is then able to accept projects with deadlines so tight, competitors are forced to decline.

Exactly How Fast Are Massivit Printers?

All of Massivit printers build at an unprecedented average speed of about 35 cm (13.7 in) per hour on the Z axis. Watch:

This perfume bottle is 1.7m (5.6ft) tall. The Massivit 1800 3D-printed it in just 5 hours!

You take or create a digital file, send it to the 3D printer, and the machine does the rest. Fast.

Wait. There is more. 3D printing allows you to skip many steps of traditional fabrication. Once the model comes off the printer, it’s ready to be finished, and installed, sometimes with no post-processing required after printing.

(Are you calculating the hours of labor you’ll save?)

3D print signs in minutes, displays in hours, and, well, take a look at what one of North America’s leading one-stop sign shops has to say. . .

Massivit 3D Printer vs. CNC

Steve Gallow of Canada-based Media Resources tested his new Massivit 1800 against his CNC machine with two models. Here is what he found out:

“A 3-foot (.9m) model of Batman took us 14 hours to make on our CNC machine and needed to be created in 2 parts. The same model on the Massivit 1800 took 6 hours to produce in 1 piece.

“Then we tested a model of a hand. It was a very complex shape for the CNC router to handle, so we were forced to split it into 16 parts and then carve for an entire day. The Massivit 1800 printed the whole thing in 1.5 hours.

“The Massivit 1800 provides a much lower cost for overall production. The machine obviously would shave months of production time off hand carving.” -Steve Gallow, Media Resources

Massivit vs CNC Machining

| MODEL | CNC | PARTS | MASSIVIT 1800 | PARTS |

|---|---|---|---|---|

| Batman | 14 hours | 2 | 6 hours | 1 |

| Hand | 12 hours | 16 | 1.5 hours | 1 |

| Bottle | 3.5 hours | 2 | 1 | 1 |

Besides speed, Massivit 3D printers are large, freeing PSPs to create any size that is needed. Let’s take a look at four projects from around the world that were successfully delivered on time because the shops had the Massivit 3D printer.

2 Giant Bottles 3D Printed Fast

Project: Two 10m (33ft.) tall bottles

Deadline: 2 weeks

3Motion was given just two weeks to produce two 10m (33ft) tall bottles and install them in Antwerp’s Central Station. With their new Massivit 1800, they could accept the job. Printing took 28 hours (total). Both bottles were fully wrapped and installed as demanded. Quite a feat, thanks to the talented team at 3Motion and their fast 3D printer. Watch the video.

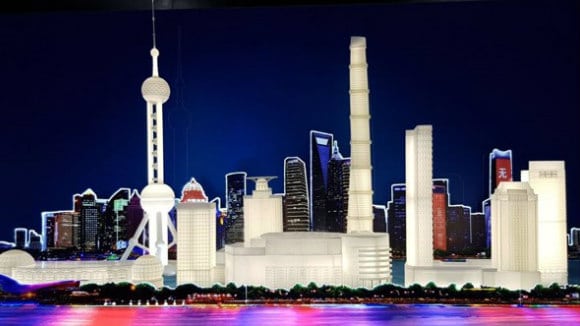

Shanghai Skyline With No Time To Spare

Project: 4.5m long and 2m high (14’9” x 6’6”) skyline

Deadline: 2 weeks

With just two weeks until the exhibition, Baicheng Digital had no time to waste to create a 3D skyline of Shanghai that included 10 buildings. Printing took 201 hours, and then they added the finishing touches including illumination and installed the 4.5m long and 2m high (14’9” x 6’6”) skyline in just 14 days.

Bringing Comic Festival Characters To Life — Quickly

Project: 5 lifesize cartoon characters

Deadline: 4 weeks

MÉTROPOLE had one month to bring 5 cartoon characters to lifesize life for the Angoulême International Comics Festival in Paris. It took 80 hours of printing followed by assembly, sculpting, and painting to complete the beautiful models. Without their fast 3D printer, they would not have been ready on time.

The president of the festival, Franck Bondoux, said, “Only the Massivit 3D printer, deployed by MÉTROPOLE, could have pulled off this feat in terms of turnaround time. Our lifesize statues were ready onsite on the opening day of the festival, creating just the wow effect we had been aiming for.”

Fashion Store’s Fast-Approaching Grand Opening

Project: 2.6m (8.5ft) tall baseball player

Deadline: Fast

printHpole came to the rescue with their Massivit 3D printer when MLB Korea wanted a captivating point of purchase display for the opening day of their new store. Their mannequin supplier could not meet the deadline and suggested printHpole because they had fast 3D printing abilities. It took just 13 hours to print and then coat the 2.6m (8.5-ft) -tall baseball player with candy paint.

A representative of MLB’s mother brand, F&F, said, “ We were very happy to be able to meet the project’s very tight time schedule. It is the first time we have worked with Massivit 3D printing and the result is far better than we expected. We loved the high quality and how this technology supported design and finishing flexibility.”

Craig Miller of Las Vegas-based Pictographics says of his Massivit printer:

“It could print me in about five hours.” -Craig Miller, Owner, Pictographics

Until the day when you can actually print another version of yourself and be able to get more work done with your duplicate, super fast 3D printing is here now to help you get work done faster. If you want to learn about the four other fabulous benefits of 3D printing, download a free copy of our ebook.