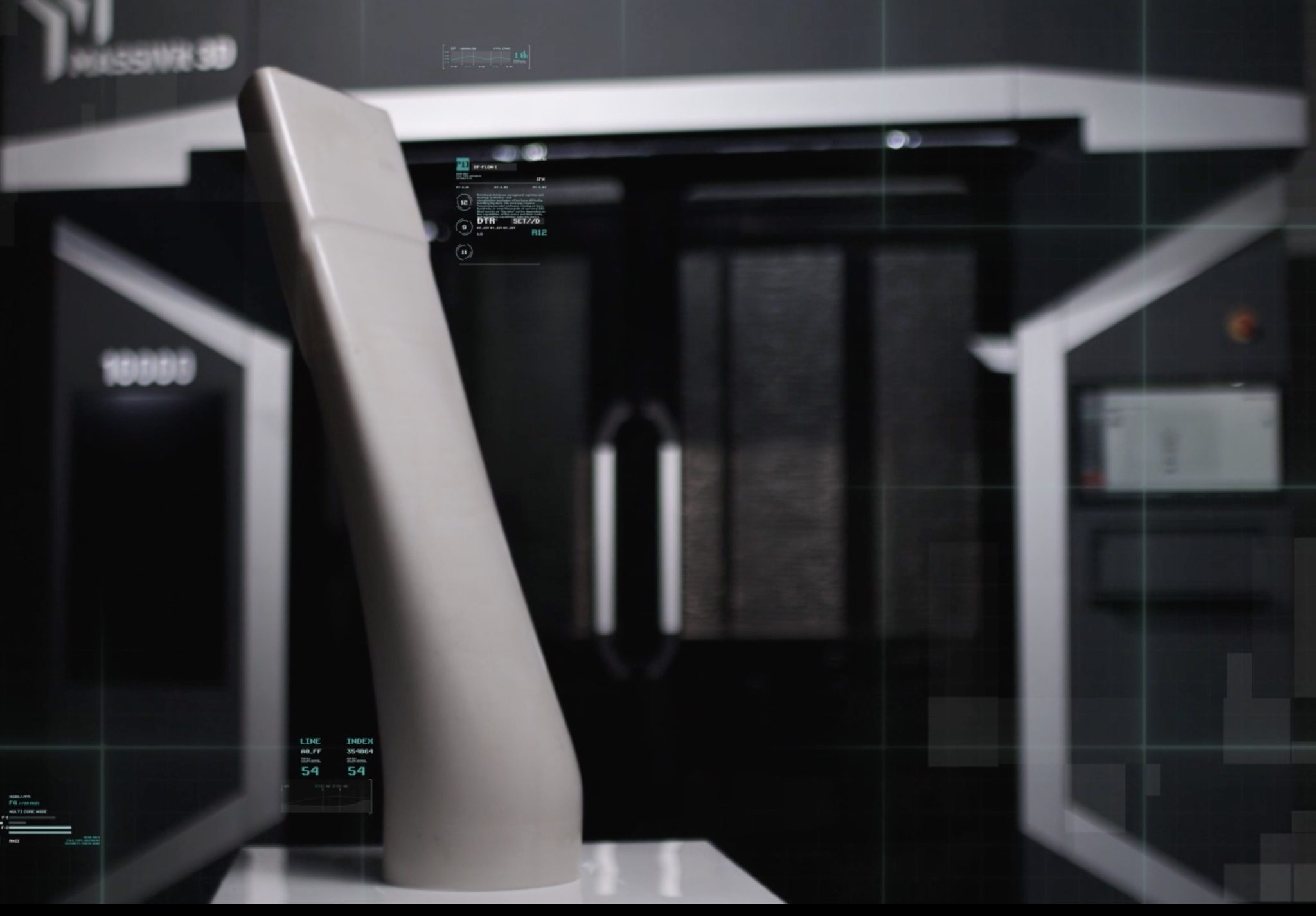

Engineers across industries can unlock faster production, precise customization, and reduced waste with 3D-printed mandrels in composite manufacturing. Learn how Massivit’s cutting-edge approach, especially with materials like the company’s water-breakable substance, streamlines manufacturing processes and enhances product quality. Read this case study to stay ahead in the evolving landscape of composite part manufacturing.