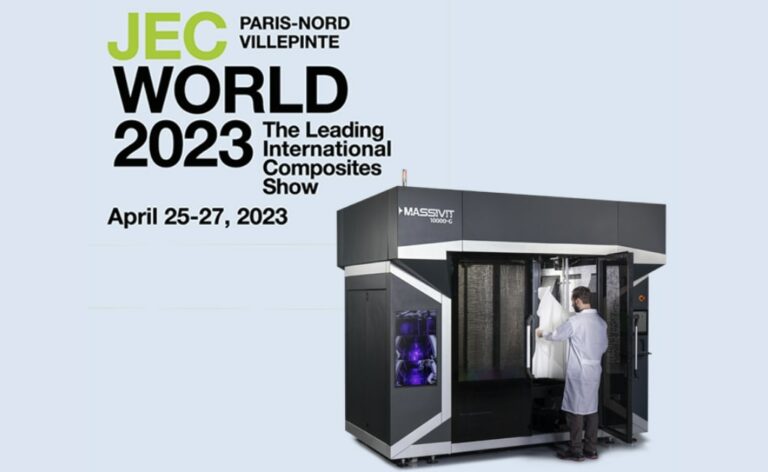

JEC World 2023 takes place at the Paris Nord Villepinte Exhibition Centre. Visitors will have the opportunity to experience live demonstrations of the Massivit 10000-G at Massivit’s Booth K58 in Hall 6 as well as a showcase of industry applications.

The system offers manufacturers significant production time and cost savings – up to 80% of mold production time and 50% in material costs. This latest industrial 3D printer on the company’s second-generation product line provides access to Massivit’s full set of Dimengel thermoset materials that have until now been available with the company’s Gel Dispensing Printing (GDP) product line. GDP enables custom manufacturing and functional prototyping at up to 30 times the speed of other technologies. The growing range of Dimengel materials respond to essential industry requirements including flame retardancy, high-definition production, and a waste reduction. GDP systems have to date been installed across 40 countries, allowing manufacturers to expedite manufacturing of large, industrial parts.

“We are thrilled to introduce the revolutionary 10000-G to the European composites market at JEC World 2023,” said Erez Zimerman, CEO of Massivit 3D. “This event is the perfect platform to showcase our latest innovations and connect with industry leaders and experts. We are confident that our 10000-G printer will disrupt composite materials manufacturing as we know it, and we can’t wait to share it with the world.”

Lance Lyons, President of Massivit’s customer Lyons Industries, concurred “Massivit’s Cast In Motion process is a game changer.”, referring to the printer’s ability to automate production. “Finally, someone’s figured out how to produce a composite mold.”

Massivit has also announced that it will utilize the JEC World event to launch its 2023 corporate rebranding roll out. The rebrand represents a significant step forward for Massivit, reflecting the company’s strategic endeavors to overcome real-world manufacturing needs by offering new, advanced additive manufacturing technologies. Massivit’s vision is to transform large-scale manufacturing from traditional processes to digital, high-speed production using industrial-grade materials. The new logo, look and feel serve to communicate Massivit’s brand identity and unique value proposition towards future growth.

The company’s rebranding process has incorporated Massivit’s core values: radical innovation, reliability – with a current install base across 40 countries, its commitment to knowledge sharing with the global AM and manufacturing communities, and a commitment to supporting greener manufacturing through waste-free, additive innovation.

Journalists are invited to book a meeting or interview with Massivit’s CEO Erez Zimerman at the show by contacting Massivit’s Marketing Team Manager below.

Images & logo can be downloaded here

About Massivit

Massivit 3D Printing Technologies Ltd. www.massivit3D.com (TASE: MSVT) is a pioneer of large-scale 3D printing solutions for the automotive, marine, railway, and furniture markets. The company’s solutions enable cost-effective production of large parts, prototypes, and molds at unprecedented speed. Massivit’s vision is to advance manufacturing of large parts from traditional, manual methods to digital production by means of ultra-fast 3D printing, using industrial-grade materials. The company was founded in 2013 by a team of experts led by Gershon Miller – founder of Objet Geometry. The company’s headquarters are based in Lod, Israel.

For further information, please contact:

Avi Cohen

VP Global Sales

Email: [email protected]

Yafit Sulimani

Senior Marketing Team Leader

Email: [email protected]

For investor relations enquiries, please contact:

Miri Segal Scharia

CEO

MS-IR LLC

Email: [email protected]

917-607-8654