In fact, shoppers spend more money in-store than online. The greatest challenge isn’t from online stores but rather how to be the retail store that shoppers spend their time in. How can shops stand out from others? How can they grab customer attention and hold on to it? This is where custom mannequins, reinvigorated by digital technology and 3D printing, can make a definite impact.

3D printed by Fluxaxis on the Massivit 1800

For retail shops that could afford the time and cost commitment, the choice of a custom mannequin to present wares, or simply draw attention, has always been attractive.

As opposed to buying mass-produced, off-the-shelf mannequins, having them custom made can better convey product and brand messaging. This creative freedom is what can set one store apart from another, and maximize foot traffic.

The problem is that traditional methods for producing custom made mannequins had created a narrow market. In addition to the high expense, the long production timeline often made it impractical.

Plenty of stores simply couldn’t afford to wait for sculptors to create mannequins out of fiberglass, clay, and metal. Even if they could, hand crafting them took so many work hours that price points were too high for most.

Thankfully, breakthrough 3D printing technology has brought down these barriers of entry. For print service providers, it opens up an entire market with a product offering that is both attractive and attainable.

The 3D Printed Mannequin Speed Advantage

Creating a custom anything will take more time than a ready-made version. This is a concept that most people accept. The difference when it comes to custom mannequins is that the time gap was so significant that it was completely infeasible for most customers. Sure, they wanted the advantages of a custom-made mannequin, but waiting weeks or even months was a non-starter. Now, large format 3D printers can produce a life-size mannequin in days or even hours. This gives PSPs with a Massivit printer a huge advantage when competing with mannequin creators who use traditional methods.

3D printed in under 8 hours by Fluxaxis

It’s not just the ability to meet a short deadline. Going so quickly from a concept on paper (or in this case, a digital file) to a prototype makes it easier for customers to place their first order. The time investment isn’t prohibitive, so they’re much more willing to give custom mannequins a shot. This also shortens the approval process. On the other hand, customers ordering a clay or fiberglass mannequin are subjected to a process that involves multiple iterations. They are, after all, created with manual labor and craftsmanship, so nobody knows exactly how it will turn out. This simply isn’t needed when you’re using a large format 3D printer that creates the final product based on a true to life digital file, and in a fraction of the time. This makes it easier for PSPs to do business, and is a relief for the customer too.

Below, Composite Images 3D prints a head.

Win-Win Pricing

It isn’t often that you can offer a product with a high profit margin while still undercutting competition in a big way. Yet, that’s exactly what large format 3D printers offer for the custom mannequin market. The cost of ordering a specialized mannequin has always been prohibitive. Small custom shops typically have exorbitant prices, while larger ones require a minimum order of 50 or more. In the end, most settle for mass-produced mannequins that are cheaper. Unfortunately, this also means they have to make do with a mediocre retail presentation.

The arrival of high quality 3D printing has created a win-win opportunity that didn’t exist before. PSPs that own a Massivit large format 3D printer can produce custom mannequins at a much lower cost, especially due to the sizable reduction in work hours needed. Since competition in the 3D space is still low, it allows print shops to enjoy a high profit margin while still passing on cost savings to their customers. Purchasing a custom mannequin then becomes a feasible option to a much larger market segment, further driving demand.

Personalization is Easy

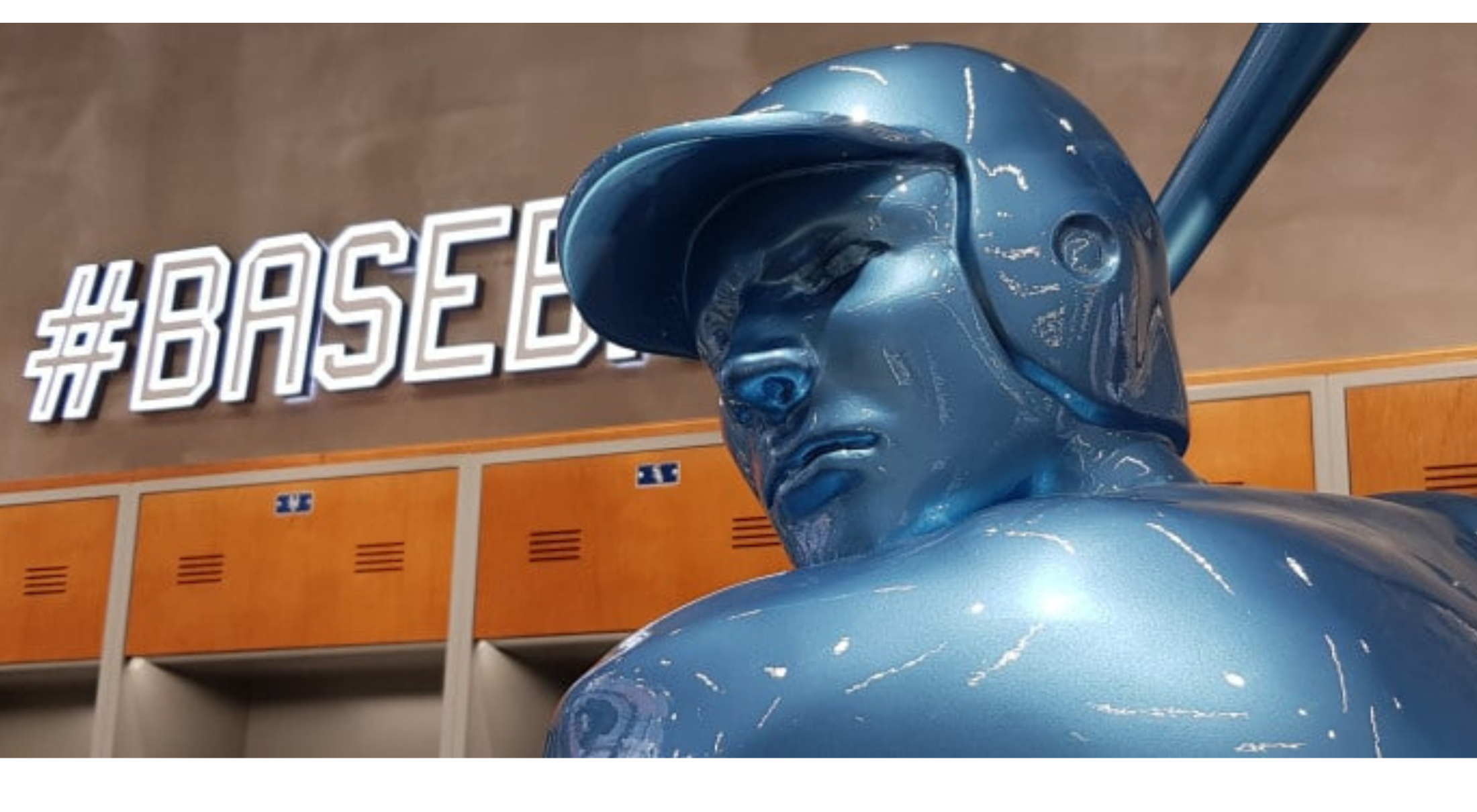

Remember, retail shops are constantly searching for ways to stand out amongst their competition. An attention-grabbing character, celebrity, or mascot can serve as the perfect option. The key is personalizing your mannequin to fit your message, and encouraging customer engagement. For example, having an 8.5ft-high (2.6m) baseball player in the middle of your shop will immediately draw eyes to it and trigger shoppers to associate in-store products with the excitement of a live baseball game. The below display for leading Korean fashion brand, F&F, was a huge hit, as customers engaged with the perfectly designed player, elegantly waiting for his pitch. Amazingly, it was printed on a Massivit 1800 in under 13 hours.

3D printed by printHpole. The customer said, “We loved the high quality and how this technology supported design and finishing flexibility.”

3D printed by printHpole. The customer said, “We loved the high quality and how this technology supported design and finishing flexibility.”Large format 3D printing allows PSPs to quickly create a personalized display that can be designed from scratch or based on an existing image or design. You can also digitally scan any celebrity, brand mascot, or character and print them in any pose, matching the exact specifications your customers desire. Since you’re working with a digital file, you can also easily change it or re-version within the existing software. With no trouble at all, you can create slightly different versions of a custom mannequin to fit different local markets or produce seasonal versions and short runs.

Below, Deko 3D by Sepia scans and 3D prints a famous female soccer player.

The Future is Here – Going Interactive

In addition to being faster to make, more cost-effective, and easy to personalize, 3D printed mannequins have another advantage over those created from traditional methods. This would be the ease in which futuristic technologies can be embedded. Adding cameras, sensors or augmented reality to a mannequin create an interactive display that is quite simply the future of customer experience. In fact, that future is already here. There’s nothing like a talking, sensing, mannequin when it comes to drawing customers in and keeping them engaged. This is the type of wow factor that can truly revolutionize the entire mannequin industry.

PSPs that are already using their large format 3D printers for OOH advertising, POP displays, and many other applications should consider adding custom mannequins to their product offerings. This is yet another opportunity for this breakthrough technology to change entire industries. Most importantly, it brings print shops, who are increasingly under the pressure of product commoditization, a real edge over their competition.

For more inspiration on 3D custom window displays, download this Ebook A Print Shop’s Guide to Spectacular 3D Window Displays.