People explore products online and then visit the mall to test or try them. Even online giants like Amazon and Zalando host physical locations, most likely to serve their customers who want to go from clicks to bricks. Here is the opportunity for PSPs to help other nearby retailers increase their business by capturing this “online” foot traffic. How? Captivating window displays. And this is where large 3D printing can help — and help PSPs develop new revenue streams.

Unlimited Possibilities in 3D-Printed Window Displays

Retailers have always made the most of their available window space with signs and lights. But 3D-style props and displays can attract even more attention.

In the past, 3-dimensional models were created with conventional subtractive fabrication methods like CNC machining or foam carving. Fabricators would use these to make point of purchase (POP) and window displays to help retailers increase store traffic.

Today, large format 3D printing offers a revolutionary solution to fabricating 3-dimensional displays: a solution that is significantly faster, offers complete customization, and removes the roof on creativity.

Large format 3D printing makes creating anything possible and PSPs around the world are proving that anything is possible, and they are setting their own profit margins.

Nespresso Window Display

Nespresso are experts at manufacturing coffee and coffee making machines. If you look at their breadth of window display advertisements, you will see they are experts in this area, too. Yet, one recent 3D-printed window display stands out even among all the other great window displays.

3D printed Nespresso window display by Composite Images*

Australian-based Composite Images used their Massivit 1800 3D printer to create this milk splash in motion to advertise Nespresso’s new centrifuge feature. The concept is creative and the execution is compelling and only achievable with Massivit. In fact, Composite Images 3D-printed two milk splash window displays, one for a smaller window in another location.

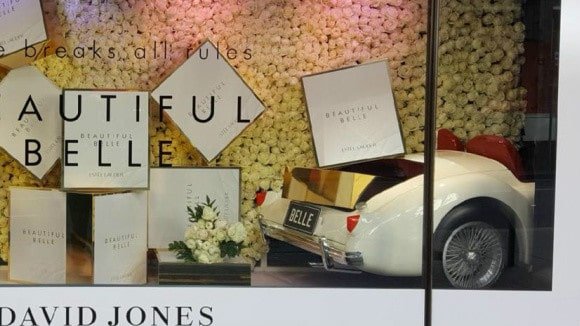

Estee Lauder Window Display

Earlier this year, Composite Images brought a touch of omnichannel advertising to this David Jones window display. The PSP 3D-printed the main empowering and exciting element in Estee Lauder’s television advertisement for the brand’s fragrance, Beautiful Belle.

The 3D-printed rear end of this classic MGA 1600 was 3D printed in only 18 hours and recreated the excitement of the TV ad for passing shoppers.

The car took just 18 hours to print on the Massivit 1800 3D printer.

Massivit Printing Puts Speed On Your Side

3D printing is digital printing technology that prints material that is layered upon itself to create a solid object. While most 3D printing technology is slow, Massivit technology is fast. Super-fast. Not only that, Massivit printers print hollow models that can be illuminated, are lightweight yet durable, and do not require support material.

All of these benefits are great, but you know how vital speed is as retailers and brands are continually changing their promotions and introducing new consumer products. Print shops have to be able to deliver quickly, and Massivit lets PSPs deliver quickly.

In fact, the technology lets you to create anything your customers desire or even have never dreamt of, faster than any other method. Even customized mannequins.

3D Printing Customized Mannequins

For a fashion store, mannequins portray the brand and display featured products. They are the all-important silent salespeople in the store and in window displays, but manufacturing mannequins is a tedious and time-consuming process. 3D printing changes that.

Steve Beckman, President and COO of custom mannequin manufacturer, Greneker, said, “3D printing produces something in 6 weeks, which would have normally taken 6 months.”

Guess what? Massivit printing technology can reduce the time to fewer than 6 days!

Speed is not the only benefit. 3D printing lets PSPs create and offer custom mannequins, even celebrity mannequins, like the 3D-printed Chris Froome mannequin by Nonkonformer. Look at the riding position of the 3D-printed Froome mannequin. It gives shoppers a real-life view of the clothing being used at peak performance.

Multiple Models And Oversized Models: Perfect For Window Displays

In Australia, SEEN Technology helped women’s fashion brand, Hermes, celebrate the Chinese New Year with a stunning window display. It showed a series of 3D-printed roosters.

3D printing uses digital files which takes away the guesswork and inaccuracies of foam carving. Duplicates, even in modified positions, are extremely easy to create with digital files.

Against a red-backdrop, all of Hermes’ roosters were exceptionally eye-catching, especially the one covered in 18K gold leaf.

3D printed Hermes window display by Seen Technology

When Roots, the Canadian clothing brand, showcased its line of puffy, winter coats, they implemented a larger-than-life 3D coat replica that captured the spotlight in the store’s window.

3D printed Roots window display by Cameron Advertising

Created by Toronto-based Cameron Advertising, this XXXL 3D-printed coat looked perfectly warm, cozy, and authentic, and it successfully drew mall visitors into the store to try on the real version. . .in a more appropriate size.

The Right Displays Keep Customers Shopping Longer

In an earlier blog, we wrote about Bertil Hulten’s 2012 experiment in Ikea that showed the longer consumers stay in a store, the more products they are likely to purchase.

Help your retail clients bring customers into stores with captivating 3D-window displays and keep them inside and engaged longer with amazing in-store displays.

MLB, a sports-centered fashion shop in South Korea, installed an expertly-painted, giant 3D-printed baseball player before the store opened, and even before the products were on the shelves!

MLB understood the importance of visual displays and contacted printHpole to 3D print this project. Using Massivit was beneficial for another reason: the display would not have been ready in time by using any other method.

That made printHpole the hero.

3D Printing Helps PSPs Keep Up With Changes

Retailers must keep their store’s visual communications fresh and new, or updated to align with their current advertising campaigns. Changing the props, mannequins, and displays regularly will keep shops and malls enticing for consumers.

Massivit puts high-speed production in your hands and lets you quickly deliver whatever new models your customers need. Get the free ebook on window displays. Download A Print Shop’s Guide to Spectacular 3D Window Displays!

*Construction Effects was the primary conceptual artist, 3D artist, designer, fabricator, and installer